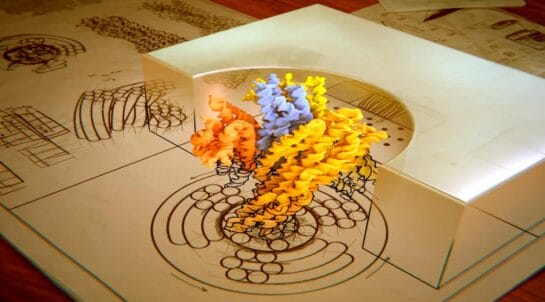

Engenheiros criam nanoturbina poderosa, construída a partir do próprio DNA, que promete revolucionar os nanomotores e as nanomáquinas no mundo!

26 de abril de 2024 —

Flavia Marinho

Craft inova com serviço exclusivo para a indústria automotiva

26 de abril de 2024 —

Corporativo

Fennix Brasil Distribuidora: líder em distribuição anuncia vagas de emprego em alguns setores; Oportunidades para motorista, estoquista, consultor de vendas e mais

26 de abril de 2024 —

Rafaela Fabris